Bavarian Hearts. Malaysian Assembled. The New BMW Engine Assembly Facility in Malaysia!

The 3rd of May 2018 marks a very important milestone for BMW Group Malaysia in conjunction with Sime Darby Auto Engineering (SADE), a division of Sime Darby Motors as they just recently opened the doors to its new 8,500 square meter SADE Engine Assembly Facility in Kulim, Kedah.

The 3rd of May 2018 marks a very important milestone for BMW Group Malaysia in conjunction with Sime Darby Auto Engineering (SADE), a division of Sime Darby Motors as they just recently opened the doors to its new 8,500 square meter SADE Engine Assembly Facility in Kulim, Kedah.

The new engine assembly facility developed through the partnership and initiatives of Sime Darby Motors and BMW Group involved a total investment of over RM132 million by SADE, and the new engine assembly facility will support BMW Groups Malaysia’s increasing demand for locally assembled vehicles.

The new engine assembly facility developed through the partnership and initiatives of Sime Darby Motors and BMW Group involved a total investment of over RM132 million by SADE, and the new engine assembly facility will support BMW Groups Malaysia’s increasing demand for locally assembled vehicles.

Ms. Ilka Horstmeier, Senior Vice President, Production Engines and Electrified Powertrains, BMW Group said: “Today is a very special day: together with SDAE we have managed to establish a new engine assembly for BMW engines in Malaysia. Our strong cooperation with our reliable partner comes to fruition with the assembly of 3- and 4-cylinder petrol engines, alongside 4-cylinder diesel engines, as well as the 3- and 4-cylinder combustion engines for the Plug-In Hybrid electric vehicle.”

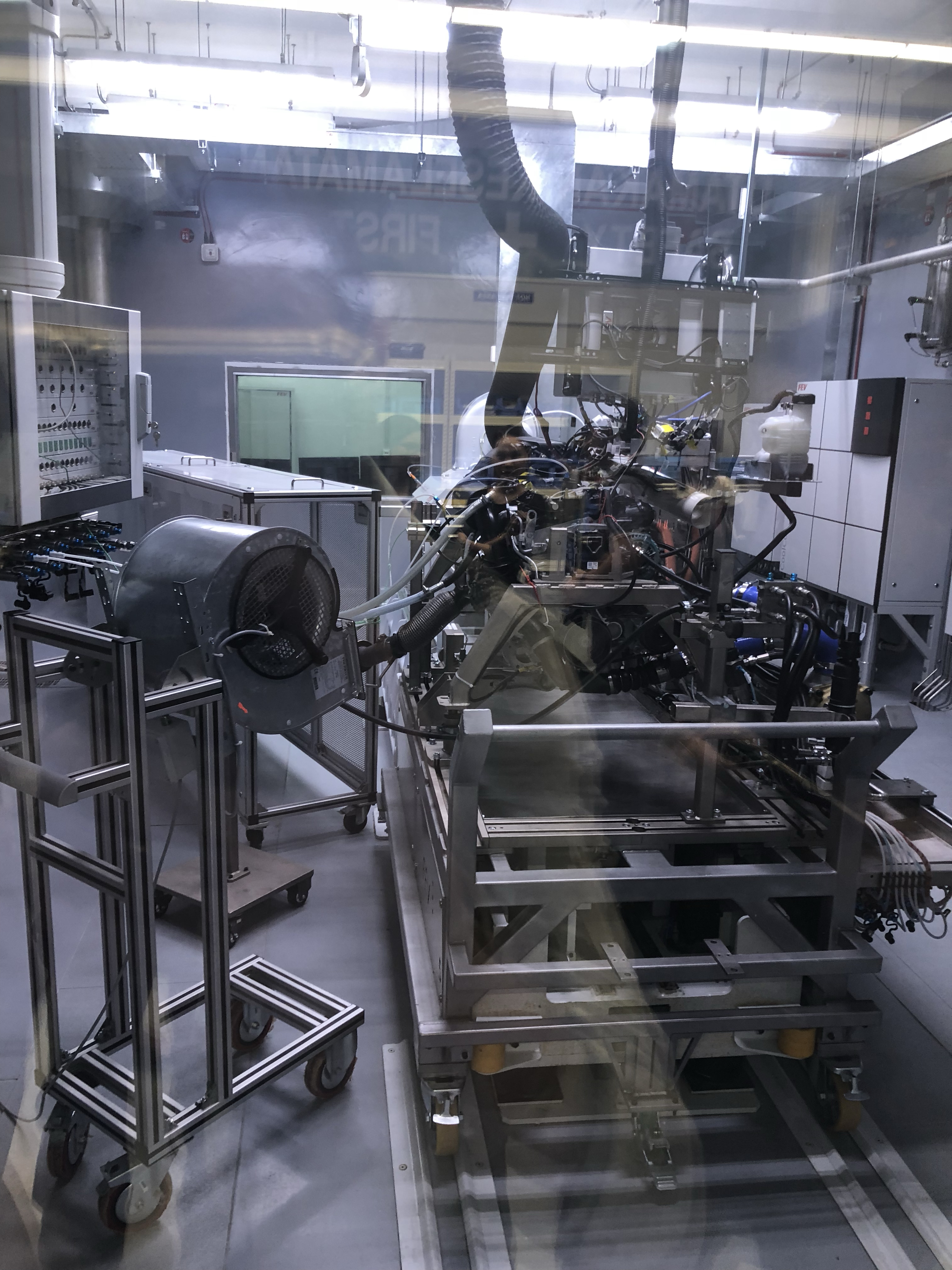

As expected from a BMW engine plant, the factory is well equipped with the newest innovation in the industry which includes EST tightening equipment, Dosing and Bonding Technology (DoboTech) equipment, engine engraving, engine oil filling and test machines for hydraulic valve play compensation, leak test as well as hot and cold testing.

As expected from a BMW engine plant, the factory is well equipped with the newest innovation in the industry which includes EST tightening equipment, Dosing and Bonding Technology (DoboTech) equipment, engine engraving, engine oil filling and test machines for hydraulic valve play compensation, leak test as well as hot and cold testing.

This new plant also employs an additional 60-person workforce demonstrating SADE & BMW Malaysia’s mutual commitment to increasing employment opportunities and career growth prospects within the local job market in the Kulim Hi-Tech area.

For quality control purposes, engines built at this assembly plant will go through a dynamic, 48 hour non-stop test, including 2 hours of performance testing and a 12 to 15 minutes hot test. While these high load tests are done on randomly hand-picked engines from 35% of its stock, 100% of engines will be tested electrically with individual bar-codes to keep track.

For quality control purposes, engines built at this assembly plant will go through a dynamic, 48 hour non-stop test, including 2 hours of performance testing and a 12 to 15 minutes hot test. While these high load tests are done on randomly hand-picked engines from 35% of its stock, 100% of engines will be tested electrically with individual bar-codes to keep track.

Engines that have gone through the physical load test will be disassembled to check individual components and any information gathered from it will be sent to BMW Germany.

Sime Darby Motors aims to produce over 50,000 vehicles including the engine parts and components for the vehicles by the year 2020. Needless to say, this new SDAE Engine Assembly Plant will bring them closer to their goals.

Sime Darby Motors aims to produce over 50,000 vehicles including the engine parts and components for the vehicles by the year 2020. Needless to say, this new SDAE Engine Assembly Plant will bring them closer to their goals.

Interesting to note is of course the assembly of BMW’s inline-4 diesel engine which might mean the inevitable reintroduction of diesel variants in our market. Excited?

Big thanks to Jonathan for the coverage!

Big thanks to Jonathan for the coverage!